The hidden EV Charging operational costs undermining profitability

Equipment costs are just the beginning for Charging Point Operators (CPOs). While DC fast chargers cost on average $50,000 and installation often exceeds equipment prices, the real EV charging operational costs are harder to spot: demand charges that dwarf electricity costs, unexpected repairs ($500–$2,000 per incident), and operational inefficiencies that drain resources.

Hidden costs are embedded throughout EV charging operations—and the operators who identify them early gain a significant advantage.

The scale of what's coming

The pressure to control costs is about to intensify. McKinsey analysis suggests Europe needs 3.4 million public charging points by 2030—requiring installations to jump from 1,600 per week in 2021 to over 10,000 per week by 2030. The total infrastructure investment could reach €240 billion by 2030, with €130 billion for charging point hardware and installation alone.

Meanwhile, market realities are harsh. Major charging providers have seen stock valuations drop over 70%, signaling investor concerns about profitability in the sector. Industry consolidation appears inevitable as weaker players struggle with mounting EV charging operational costs.

This massive buildout combined with market pressures means hidden costs that seem manageable now will multiply rapidly. CPOs who don't identify and control these expenses early will find themselves squeezed as competition intensifies and margins shrink.

Hidden operational costs CPOs should know about

Understanding these hidden expenses isn't just about protecting profits – it's about maintaining high uptime and delivering reliable service to EV drivers.

1. Fragmented operations drain resources

As EV charging networks scale, CPOs often work with a diverse mix of hardware, software, and payment partners. This multi-vendor approach brings flexibility and access to best-in-class solutions, but it also introduces significant financial complexity behind the scenes.

Manual reconciliation and data silos: Each charging session generates transaction records that must be matched, validated, and settled across different systems – often requiring manual intervention from finance teams. For large operators, this can mean dedicating additional resources to back-office processes like invoicing, reconciliation, and compliance reviews.

Increased risk of revenue leakage: Disparate systems and manual workflows increase the likelihood of errors, missed transactions, or delayed settlements, directly impacting cash flow and profitability.

Operational drag: As transaction volumes grow, so does the administrative burden, diverting resources away from core priorities like uptime, maintenance, and customer experience. Streamlined operations through integrated solutions eliminate much of this hidden labor cost. CPOs can redirect those resources toward uptime and customer service instead of administrative busywork.

2. Downtime costs more than repair bills

Unexpected equipment failures hit CPOs multiple ways. Direct repair costs range from $500–$2,000 per incident. But the real damage goes deeper. The reliability crisis affects the entire industry. Analysis of 13 million charging sessions shows that 9 out of every 100 charging attempts fail, according to Kempower data. While 81% of failures stem from user issues like authentication problems, the remaining 19% are technical faults that CPOs must address. Each breakdown means:

- Lost revenue from unused capacity

- Frustrated drivers who switch to competitors

- Risk of losing government subsidies tied to uptime requirements

Proactive maintenance and real-time diagnostics cost money upfront but prevent expensive surprises later.

3. VAT compliance complexity

Cross-border equipment sourcing and multiple revenue streams create unexpected VAT compliance burdens. A single charging session can trigger different VAT rates depending on location.

MSPs face even greater complexity. When customers charge across borders, each session must be tracked by location, taxed correctly, and consolidated into compliant invoices. Miss the reverse charge mechanism requirements, and penalties follow quickly.

Manual reconciliation and VAT errors don't just slow down payments—they result in regulatory fines, failed audits, and missed expansion opportunities as CPOs struggle to keep up with transaction volume.

The administrative overhead compounds rapidly. Finance teams spend hours on manual reconciliation, compliance reviews, and corrections. Many operators discover they need specialized tax expertise, automated VAT management systems, and dedicated staff – costs that weren't in the original business plan.

For a detailed breakdown of cross-border VAT challenges and solutions, read our analysis: Simplifying VAT Complexity in Cross-Border EV Charging.

4. Software and connectivity fees create ongoing budget pressure

We noted the visible costs for charging hardware—the software expenses often catch operators off guard. Annual licensing can range from $100–$300 per charger, with network connectivity adding another $30–$100 per port monthly, according to industry benchmarks. That's up to $300,000 a year for a 1,000-charger network—before adding roaming, diagnostics, or advanced tariff logic.

For operators managing multiple locations across different markets, these recurring costs compound quickly.

Smart operators, however, view this software infrastructure as essential revenue enablement, not just operational overhead.

The key is selecting platforms that deliver measurable operational efficiency. Look for solutions that automate manual functions, reduce workload, and handle regulatory compliance seamlessly.

When software reduces operational friction and speeds revenue recognition, the monthly fees become a lever for scale, and not just an overhead line.

5. Poor experience drives away revenue

The most expensive hidden cost isn't financial – it's lost customers.

Non-functional chargers, confusing payment systems, and poor customer support drive users to competing networks. Each frustrated driver represents lost utilization and revenue over time.

Investing in seamless user experiences and responsive support builds loyalty and maximizes revenue from existing infrastructure.

Focus on what matters

By identifying and managing these hidden costs, CPOs can free up working capital to focus on what matters most: maximizing charger uptime, ensuring reliable driver experiences, and building sustainable, profitable charging businesses.

The operators who recognize these hidden costs early gain a significant advantage over those who discover them the expensive way.

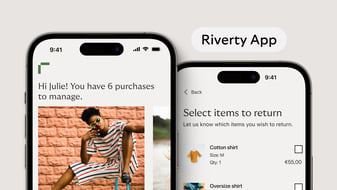

Financial Solutions for the EV-Charging Industry

Riverty simplifies payment management for e-charging stations. Reduce your accounting costs by up to 30% with our automated processes.